The global nutritional gummy market is expanding at an astonishing pace. According to a report by Grand View Research, the market size is projected to reach tens of billions of US dollars by 2030, with a Compound Annual Growth Rate (CAGR) exceeding 10%.

This explosive growth is primarily driven by a shift in consumer preference toward gummy supplements, which are convenient, delicious, and easy to consume, especially among children, young women, and individuals who have difficulty swallowing pills.

For brands, gummies are more than just supplements; they are a powerful marketing tool. They offer limitless creative possibilities and significantly improve user adherence.

So, how exactly are these delicious and effective gummies made? And what are the market opportunities and challenges behind their production? Let’s dive into the step-by-step process of gummy supplement manufacturing.

What Are Gummy Supplements Made Of?

The secret behind every high-quality gummy lies in its carefully balanced formula. Core components include:

1. Base Gelling Agents

These form the “skeleton” of the gummy. While gelatin (animal-derived, offering a chewy texture) is traditionally used, plant-based alternatives like pectin (fruit-derived) and starch are increasingly popular to meet vegetarian and vegan demands.

2. Functional Ingredients

These are the core value of the gummy, including but not limited to:

- Vitamins (e.g., Vitamin C, D, B complex)

- Minerals (e.g., calcium, iron, zinc)

- Herbal extracts (e.g., elderberry, turmeric)

- Innovative ingredients (e.g., probiotics, collagen, melatonin)

3. Flavoring and Sweetening System

This ensures an enjoyable sensory experience. Market trends are rapidly shifting toward clean labels:

- Natural Sweeteners: Preference for natural or low-glycemic sweeteners like monk fruit extract, stevia, and erythritol to achieve sugar-free or low-sugar formulations.

- Natural Flavors: Use of natural flavorings or real fruit extracts for taste and color, avoiding artificial colors and flavors to align with consumer demand for pure, natural ingredients.

The Gummy Manufacturing Process

Creating gummy supplements blends food science and pharmaceutical expertise. The main steps in the gummy supplement manufacturing process are as follows:

Step 1: Formula Design and Small-Scale Prototyping

This is the starting point for every successful product. The supplement contract manufacturer’s R&D team works closely with the brand to determine the optimal formula based on the target efficacy, taste preference, and budget. Small-scale trials are conducted in the lab to ensure ingredient compatibility, accurate dosing, and acceptable taste.

Step 2: Mixing and Heating Process

Base ingredients such as water, sugar/sweeteners, and gelling agents (gelatin or pectin) are mixed and gently heated in large, jacketed kettles to form a uniform syrup matrix. Temperature control is crucial; excessive heat can destroy ingredients, while insufficient heat affects dissolution.

Step 3: Dosing and Homogenization

After the base syrup cools to an appropriate temperature, heat-sensitive functional ingredients (like vitamins, probiotics), acidulants, colorants, and flavorings are added. The mixture is then rapidly stirred using a homogenization device to ensure the active ingredients are precisely and consistently distributed throughout every single gummy.

Step 4: Depositing, Molding, and Cooling

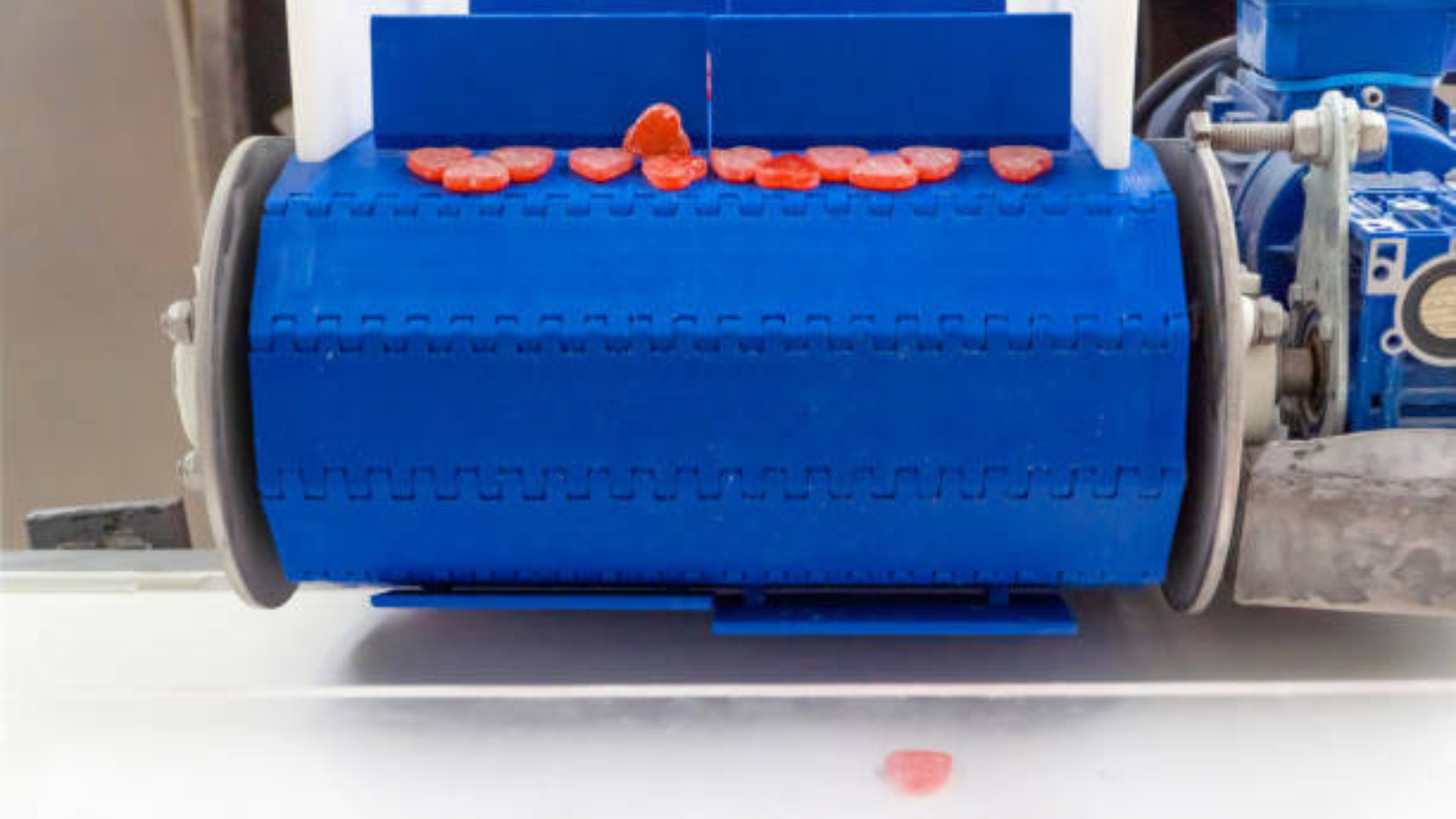

The homogenized liquid gummy mass is injected into customized molds using a precision depositor. The mold determines the final shape of the gummy (bears, fruits, brand logos, etc.). Subsequently, the gummies are sent through a cooling tunnel for rapid setting.

Step 5: Drying, Polishing, and Packaging

The surface of the set gummies may be slightly sticky, requiring them to be held in a drying room for a specific period to achieve the desired texture and moisture content. Some products are polished to give them a shinier appearance. Finally, they are individually wrapped or bottled via an automated packaging line, often using inert gas like nitrogen to extend shelf life.

Step 6: Rigorous Quality Inspection

Quality control is applied throughout the entire production process. The finished product undergoes a series of strict tests, including active ingredient assay, microbial limit testing, and sensory evaluation, to ensure every batch is safe, effective, and compliant with regulations.

Why Gummies Are More Popular Than Capsules?

This popularity primarily stems from the gummies’ unparalleled user experience:

- Excellent Consumption Experience: The delicious taste transforms nutritional supplementation from a “chore” into a “enjoyment”, significantly boosting user retention and the likelihood of consistent use.

- Unlimited Creative Potential: The shape, color, and flavor can all be customized, offering immense space for brand storytelling and visual marketing.

- Clear Niche Market: They hold a natural appeal for children, adults who dislike swallowing pills, and younger demographics pursuing a trendy and healthy lifestyle.

How to Ensure the Efficacy and Stability of Gummy Supplements?

Gummy supplement stability is a top brand concern and the true test of a manufacturer’s technical skill. While the inherent moisture and heat challenge certain ingredients, advanced technologies now provide effective solutions.

Microencapsulation and Embedding Technology

This serves as a “golden shield” to protect sensitive ingredients (such as probiotics, Vitamin C, and Omega-3s). Active compounds are coated with a special wall material to isolate them from external factors (oxygen, moisture, heat) and ensure they remain active until released inside the body, maintaining efficacy throughout the shelf life.

Low-Temperature Processing

Special low-temperature dosing and mixing processes are developed for extremely heat-sensitive components to prevent degradation during manufacturing.

Scientific Shelf-Life Management

Product expiration dates are determined through accelerated stability testing. Furthermore, moisture-proof and oxygen-barrier packaging (such as aluminum foil pouches and the inclusion of desiccants) is used to maintain product quality.

How Manufacturers Help Brands Stand Out?

In a competitive, homogenized market, differentiation is key to success. An excellent supplement manufacturer provides the following innovation support:

Dosage Form Innovation:

- Dual/Multi-Layer Gummies: Combine different flavors or ingredients in a single gummy for a unique texture and compound effect.

- Liquid-Core Gummies: Feature a firm outer shell and a soft inner core, often used to encapsulate functional oils (e.g., DHA, Vitamin E).

- Functional Compound Gummies: Cleverly combine multiple functions, such as “Beauty + Sleep Aid” or “Energy + Eye Care.”

Functional Innovation: Stay current with market trends by developing scientifically formulated recipes for specific needs, including sleep, mood management, beauty and anti-aging, sports recovery, and immune support.

Sustainability and Clean Label: Offer options like plant-based (vegan), sugar-free, non-GMO, and organic ingredients to meet modern consumer demand for health and environmental responsibility.

Regulations and Compliance Essentials for Gummy Supplements

Regulatory oversight for gummies is becoming stricter in major global markets, making compliance the cornerstone for product launch and success.

Key Labeling Requirements

Mandatory Disclosure: The label must clearly state all ingredients, amount per serving, recommended daily intake, a nutrition/supplement facts panel, and allergen information.

Global Market Differences

| Market | Regulatory Body | Compliance Point | Key Restriction |

| United States | FDA | Regulated as Dietary Supplements (under DSHEA). Must comply with cGMP (Current Good Manufacturing Practice) requirements. | Cannot claim to treat, cure, or prevent any disease. |

| European Union | EFSA | All health claims must be pre-approved by the European Food Safety Authority (EFSA) and listed in the EU register of authorized claims. | Stringent pre-approval required for all functional claims. |

| China | Varies | Products claiming a health function must apply for and obtain the “Blue Hat” registration, a rigorous and complex process. | If sold without the “Blue Hat,” they can only be marketed as general food with no health claims. |

Marketing and Promotional Compliance

- Scientific Basis: All marketing materials and claims must be substantiated by scientific evidence. Exaggerated claims about therapeutic effects are strictly prohibited.

- Manufacturer Support: The supplement contract manufacturer should be able to provide the necessary scientific evidence and supporting documentation for the ingredients used.

Gummy Supplement Manufacturing Trends

The future gummy market will exhibit the following key trends, offering new opportunities for brands:

- From “Single” to “Compound” Functionality: Consumers are increasingly looking for a single gummy to address multiple health concerns. Multi-functional, compound formulas are becoming the mainstream.

- Clean Label and Health Focus: “Sugar-free,” “all-natural,” and “clean label” have become critical purchasing decision factors, reflecting a focus on healthier ingredients.

- Personalized Customization: Custom-formulated or custom-flavored gummies based on user health data could be a disruptive future innovation in the market.

- Packaging Innovation: Smaller packs, on-the-go pouches, and exquisite gift boxes are growing in popularity, catering to consumer needs for portability and gifting.

Conclusion

Gummy supplements have become the hottest dosage form for functional nutrition, serving as the key to achieving brand differentiation and growth. The core of success lies in selecting a partner with proven gummy manufacturing expertise, flexible production capacity, and rigorous compliance capabilities.

We are a leading nutritional supplement contract manufacturer, providing an all-in-one service from market insights, formula R&D, and pilot sampling to scaled production and regulatory support. Contact us now to secure your market advantage and accelerate your gummy product launch!