In the contemporary health and wellness industry, powdered supplements are gaining rapid popularity and reshaping how people consume nutrition. According to data from Grand View Research, the global market for powdered dietary supplements reached a valuation of $27.93 billion in 2024 and is projected to exceed $51.706 billion by 2030, with a compound annual growth rate (CAGR) of 10.9%.

A survey by the Nutrition Business Journal (NBJ) also reveals that powdered supplements are particularly favored among younger consumers: 53% of Gen Z, 43% of Millennials, and 41% of Gen X use them regularly. Even among Baby Boomers, 10% have adopted this supplement format.

In our previous article, “Supplement Forms Explained: Capsules, Tablets, Powders,” we explored the advantages of powder supplements. Their flexible dosing, efficient absorption, and customizable flavors allow consumers to personalize their supplements to their needs and achieve a superior user experience. These advantages not only increase satisfaction but also significantly boost repeat purchase intentions, making powder supplements highly popular in the market.

For supplement brands, powdered products represent more than a line extension—they are a strategic tool for differentiation. This guide offers a detailed, step-by-step overview of the powdered supplement manufacturing process, empowering brand owners to successfully enter this expanding market.

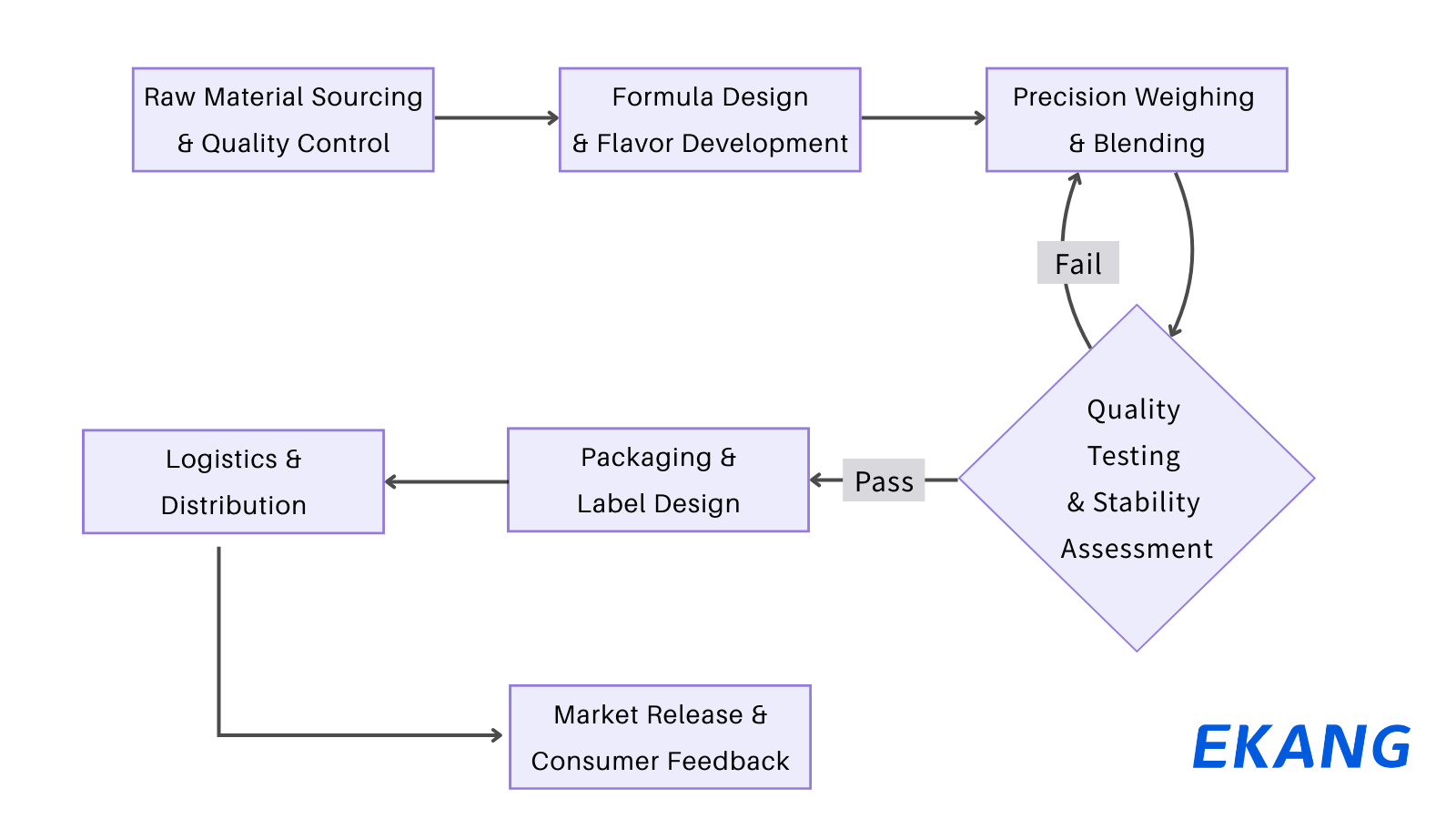

How Are Powdered Supplements Manufactured?

The production of powdered supplements is far from a simple mixing process; instead, it is a tightly integrated series of steps. From raw material selection and formula design to blending, testing, and finally, packaging and logistics, every single step directly influences the product’s efficacy, safety, and consistency. In the following sections, we will break down this complete process step by step.

Step 1: Raw Material Sourcing and Quality Control

High-quality raw materials are the foundation of any successful powder supplement. The quality of these ingredients directly determines the product’s potential. No matter how good the formulation, if the raw materials are subpar, the product will struggle to gain a foothold in a competitive market.

Premium ingredients are typically sourced from suppliers who follow Good Manufacturing Practices (GMP) and hold certifications such as non-GMO or organic. These certifications not only serve as a promise of quality to the consumer but are also crucial for a brand to build a competitive advantage.

The core types of raw materials for powder supplements include, but are not limited to:

- Protein Powders: Such as whey, pea, and soy protein, which are common choices for sports nutrition supplements.

- Vitamins and Minerals: Essential for maintaining overall health and immune function.

- Amino Acids: Helpful for muscle repair and energy metabolism.

- Herbal Extracts: These provide unique functional benefits to the product and enhance market differentiation.

However, ingredients must be more than just “effective”; they also need to “perform well.” Their solubility, stability, and taste directly impact the consumer experience. Imagine a scoop of protein powder that clumps after mixing, or a vitamin drink with a bitter aftertaste—consumers are unlikely to give it a second chance.

Thus, sourcing raw materials is far more than a routine operation—it is the most critical stage in manufacturing powder supplements. Only by maintaining rigorous control from the origin can a final product achieve market trust and build a strong reputation.

Step 2: Supplement Formula Design and Flavoring

If raw materials are the foundation of a product, then the formulation is the blueprint that determines its success or failure. It not only defines the product’s function and uniqueness but also directly influences a consumer’s willingness to use it long-term.

An excellent formula design must be both scientific and market-driven.

Scientific: This ensures that ingredients work synergistically. For example, combining protein with specific amino acids can improve muscle repair, while pairing vitamins with minerals can boost immunity. All formulations must also comply with strict regulations and safety standards.

Market-Driven: The formula must closely follow consumer demand. The recent popularity of “sugar-free” and “plant-based” trends has led us to widely use plant proteins and natural sweeteners.

However, what truly makes consumers “fall in love” with a product is often the flavor. The importance of taste can even outweigh function during the initial experience.

- We prefer to use natural flavorings and sweeteners (like stevia and monk fruit) to reduce the sugar load.

- Diverse flavors (vanilla, chocolate, matcha, etc.) can meet the preferences of different demographics.

- Optimizing texture (like smoothness and solubility) helps consumers build a consistent usage habit.

In short, a scientific formula makes a product “effective,” while a thoughtful flavor design makes it “delicious.” Only a combination of both can create a true market hit.

Step 3: Precise Weighing and Blending

After the formula design is complete, the product enters the core manufacturing stage. Precise weighing and blending are crucial for ensuring the quality and consistency of powder supplements.

First is precise weighing. The amount of each nutritional ingredient must strictly adhere to the formula. Even a deviation of a few micrograms can affect the final product’s efficacy and safety. We use high-precision electronic scales and automated dosing systems to ensure every ingredient is measured with perfect accuracy.

Next is the blending process, which aims for a uniform distribution of all ingredients at both macroscopic and microscopic levels.

- If the blend is not uniform, sports nutrition powders might have inconsistent flavors, and multivitamin powders could have varying nutritional content per scoop, directly impacting the product’s effectiveness and user experience.

We select the appropriate blending equipment based on the characteristics of different formulas, such as:

- V-blenders: Ideal for large-batch, uniform mixing.

- Ribbon blenders: Suitable for powders with poor flowability.

- High-speed mixers: Used for the rapid dispersion of small batches of functional powders.

Additionally, we strictly control the powder’s particle size, moisture content, and static electricity during blending, as these factors can affect uniformity and final solubility. A professional manufacturer will conduct multiple tests to ensure that every batch of the product has consistently excellent quality.

It’s fair to say that precise weighing and mixing are the “unseen forces” behind product quality—though invisible to consumers, they are crucial to building a reputable product.

Step 4: Quality Control and Stability Assessment

Quality control isn’t an extra step in powder supplement manufacturing; it’s a core guarantee that runs through every stage. Ensuring a product is safe, stable, and reliable is key to earning consumer trust.

1.Comprehensive Quality Testing

We perform multi-dimensional testing on both raw materials and finished products:

- Physical Property Testing: Key indicators such as particle size, flowability, and moisture content directly affect dissolution performance and shelf life.

- Chemical Composition Testing: Strictly ensure active ingredient consistency with label claims and control potential risks such as heavy metals and pesticide residues.

- Microbial Testing: Given that powders are prone to moisture absorption—which may lead to mold or bacterial contamination—microbial limit testing is especially critical.

2.Stability Assessment

Even if a product meets standards upon leaving the factory, we must ensure it maintains its efficacy and taste after transportation, storage, and long-term use.

- Accelerated Shelf-Life Testing: We simulate high-temperature and high-humidity environments to check if the product will discolor, clump, or lose effectiveness.

- Dissolution and Solubility Testing: We ensure the powder dissolves easily, without clumping or settling.

3.Ensuring Batch Consistency

To guarantee that consumers have the same experience with every purchase, we implement a strict batch retention system and conduct multiple sample checks during production. This ensures that every single batch meets the highest standards.

It can be said that quality control and stability assessment are the “gatekeepers” for powder supplements entering the market. Only by passing these rigorous tests can a product stand firm in a competitive marketplace.

Step 5: Supplement Packaging and Label Design

After successful manufacturing and quality control, powder supplements enter their final critical stage: packaging and label design. This step not only determines the product’s preservation and transport but also directly influences a consumer’s purchasing decision.

1.Packaging Form and Materials

There are various packaging forms, with the most common being:

- Bottles: Suitable for long-term storage and daily use.

- Pouches or single-serving sachets: Convenient for travel and for controlling a single dose.

The packaging materials must be moisture-proof, light-proof, and oxidation-proof to ensure the powder’s stability during transport and storage.

2.Label Design and Regulatory Compliance

The label is key to a brand’s image and information delivery. During the design process, it’s crucial to ensure:

- Regulatory Compliance: Strict adherence to requirements from regulatory bodies like the FDA and the EU, with clear labeling of ingredients, nutritional information, and allergens.

- Clear Information: Allowing consumers to quickly understand the product’s benefits, usage, and precautions.

- Visual Appeal: Using color, font, and graphics to make the product stand out among competitors.

3.Optimizing User Experience

Excellent packaging design also considers the user experience, including ease of opening, accessibility of the powder, and leak-proof features. These details enhance consumer convenience and brand loyalty.

In short, packaging and labeling are the product’s “attire” and a vital bridge connecting the brand with consumers. Thoughtfully designed packaging can make a product stand out in a fierce market.

Step 6: Logistics and Distribution Channels

From the production line to the consumer’s hands, a powdered supplement must navigate a strict logistics and distribution process. This step is not just about ensuring the product arrives safely; it’s also vital for brand reputation and market performance.

1.Storage and Transport Management

Because powder supplements are sensitive to moisture, temperature, and light, their storage and transport require strict controls:

- Temperature and Humidity Control: Maintaining low humidity and a stable temperature prevents the product from clumping or spoiling.

- Protective Packaging: Using crush-resistant, leak-proof packaging avoids damage during transit.

- Batch Tracking: Employing barcodes or batch codes enables full-chain traceability, which is crucial for quality management and recalls.

2.Distribution Channel Strategy

Choosing the right distribution model depends on the brand’s positioning and target audience:

- E-commerce Platforms: These provide direct access to consumers, facilitating new product promotions and customer data collection.

- Retail Channels: Enhance offline visibility and purchase convenience, expanding market reach.

- Direct Sales/Subscription Services: Build stable customer relationships, encouraging repeat purchases and long-term loyalty.

3.The Role of Logistics in Brand Building

Logistics isn’t just a delivery function; it’s a key touchpoint for conveying brand value:

- Delivery Quality: Punctual delivery and undamaged packaging significantly boost customer satisfaction.

- Information Transparency: Providing real-time tracking enhances trust.

- Integrated Marketing: Combining promotions, collaborations with key opinion leaders (KOLs), and social media communication helps build a complete consumer loop from awareness to loyalty.

In summary, logistics and distribution are the bridges connecting a product to the market. Their efficiency and the experience they provide directly determine whether a brand can consistently earn customer recognition in a competitive landscape.

Conclusion and Brand Building Suggestions

From raw materials and formulation to blending, testing, packaging, and logistics, every single step is crucial to ensuring powdered supplements are safe, stable, and user-friendly.

While manufacturing a high-quality product is essential, brands should also focus on their market strategy:

- Be consumer-centric: Different groups have different preferences for flavor and function.

- Innovate continuously: Keep your formulas, flavors, and packaging materials competitive.

- Enforce strict quality control and compliance: Ensure your product is safe and reliable.

- Integrate your marketing and distribution strategies: Create a closed-loop system using e-commerce, retail, and social media.

A powdered supplement is more than just a product format; it is a brand strategy. By mastering the complete manufacturing process and combining it with a scientific market strategy, a brand can achieve lasting competitiveness in the health industry.

Are you ready to bring your high-quality, great-tasting, custom powdered supplement to the market? If you have specific project needs, please contact our experienced business managers for a professional consultation.